Frequently Asked Questions

How is silicone produced?

The silicone production process can be divided into the following stages:

- Extraction and processing of raw materials: The primary raw material used to produce silicone is silica sand (SiO₂). Silica sand is mined from sand deposits or gravel sources. It is then processed to remove impurities such as iron, aluminum, and calcium.

- Production of Trichlorosilane (TCS): TCS is an intermediate compound used in silicone manufacturing. It is produced by reacting silicon tetrachloride (SiCl₄) gas with hydrogen (H₂).

- TCS purification: TCS is purified to remove impurities and increase its purity level.

- Silicon casting: TCS is used to create pure silicon ingots. These ingots are later used in subsequent stages of silicone production.

- Silicon refining: Silicon is refined using methods such as electrolysis, metal reduction, or melting.

- Silicone processing: Pure silicon is then processed into various silicone products, such as silicon wafers, silicon rods, or silicon powder.

What are the quality standards for silicone?

In Vietnam, silicone quality standards are regulated by the following organizations:

- National Standards: TCVN 8266:2009

- Industry Standards: TCVN 8266-1:2009, TCVN 8266-2:2009, TCVN 8266-3:2009

TCVN 8266:2009 defines quality requirements for pure silicon and silicon alloys. It applies to silicon used in electronics, energy, industrial applications, and construction.

This standard specifies requirements for the following properties:

-

Chemical composition: Levels of impurities in silicon

-

Purity: Degree of silicon purity

-

Electrical conductivity: Conductivity performance

-

Strength: Mechanical durability

TCVN 8266-1:2009: Specifies the quality requirements for pure silicon with 98.5% – 99.99% purity, used in electronics, energy, and industrial sectors.

TCVN 8266-2:2009: Specifies the quality requirements for silicon alloys with 98.5% – 99.99% purity.

TCVN 8266-3:2009: Specifies the requirements for pure silicon and silicon alloys with ≥99.99% purity, used in high-end electronics and special applications.

In addition to national standards, silicone is also produced and used according to international standards, including:

- ASTM C1184

- ISO 642

- DIN EN 576

These international standards may apply depending on specific industries or applications.

Silicone Manufacturing Certifications at MINH FAST

MINH FAST’s silicone factory has obtained the following quality certifications:

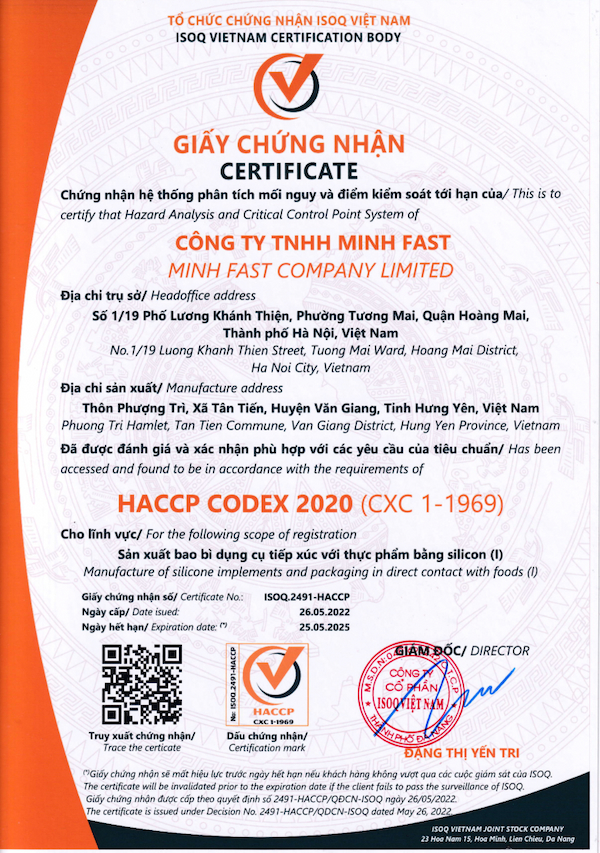

HACCP Certification:

This certifies that the factory’s food safety management system meets HACCP requirements. HACCP is a preventive system designed to identify and control food safety hazards.

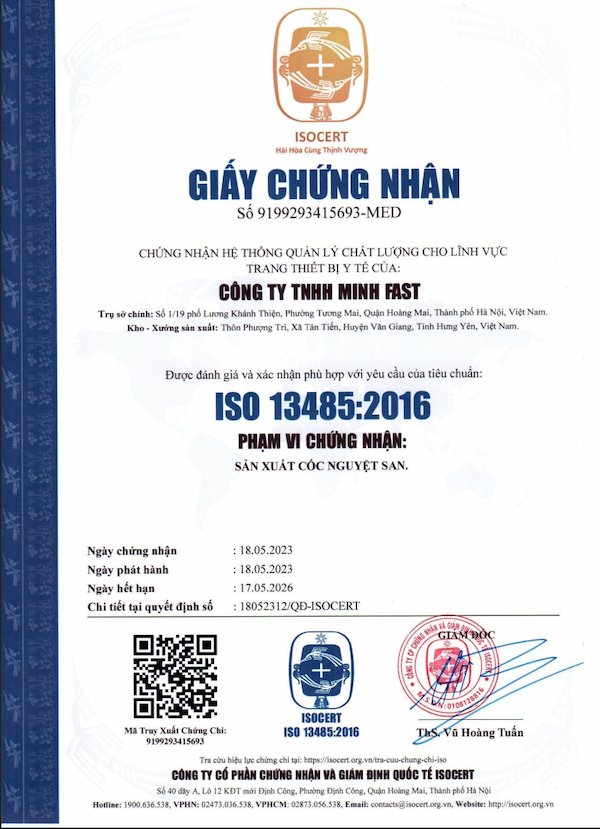

Product Testing & Quality Declaration:

MINH FAST products are tested and certified according to national and international standards. Below is the ISO 13485 certification—the quality and safety management system for medical devices.

ISO 9001:2015 Certification:

This certification confirms that the factory’s quality management system meets ISO 9001 requirements—an international standard covering processes, products, services, and customer satisfaction.

These certifications ensure that MINH FAST consistently delivers high-quality silicone products that meet customer requirements and ensure consumer safety.

Tel : 0936.08.03.82

MINH FAST COMPANY LIMITED

Office address: No 1/19 Luong Khanh Thien Street , Hoang Mai Ward,, Hanoi, Vietnam.

Factory : Km 33 – ĐT 379 – Văn Giang – Hưng Yên

Tel: 0936.08.03.82

Email: Minhfastsales@gmail.com

Fanpage: https://www.facebook.com/minhfastsilicone

Website: https://giacongsilicone.com