Silicone Production Order Process

Custom Silicone Rubber Manufacturing Process (Based on Customer Requirements)

1. Customer Sends Inquiry

Customers with a need: The customer has an idea or a product that needs to be made from silicone and sends the request to Minh Fast.

Information to provide: To ensure accuracy, customers should provide as much detail as possible, such as:

-

Photos or 3D drawings (if available)

-

Desired size, thickness, and color

-

Suitable silicone material (e.g., liquid silicone, solid silicone, heat-resistant silicone, etc.)

-

Required quantity

-

Expected delivery time

-

Any special requirements (if any)

2. Quotation

Minh Fast evaluation: Based on the information provided, Minh Fast evaluates product complexity, selects suitable materials, and calculates production costs.

Detailed quotation: Minh Fast will send a full quotation including:

-

Product cost

-

Estimated production time

-

Payment terms

-

Other conditions (if applicable)

3. Sample Production

Creating sample: Minh Fast produces a prototype based on the approved information.

Sending sample: The sample will be sent to the customer for inspection and approval.

4. Customer Reviews & Approves the Sample

Sample inspection: The customer thoroughly checks the sample for:

-

Dimensions

-

Shape

-

Surface quality

-

Color

-

Other properties (e.g., hardness, durability, etc.)

Approval or revision request:

- If the sample meets requirements, the customer approves it.

- If not, adjustments will be made as requested.

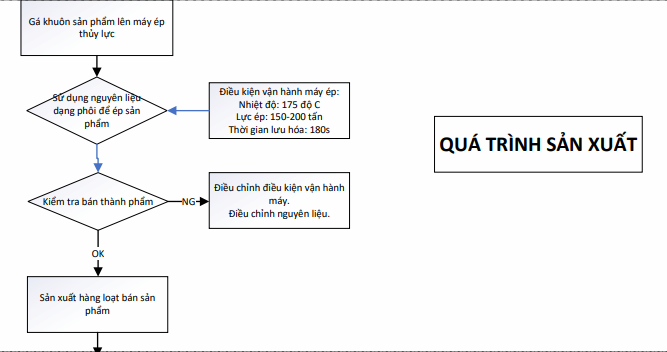

5. Mass Production

- Mold preparation: After the sample is approved, the mold for mass production is manufactured.

- Production: Silicone material is injected into the mold and vulcanized to create the final product.

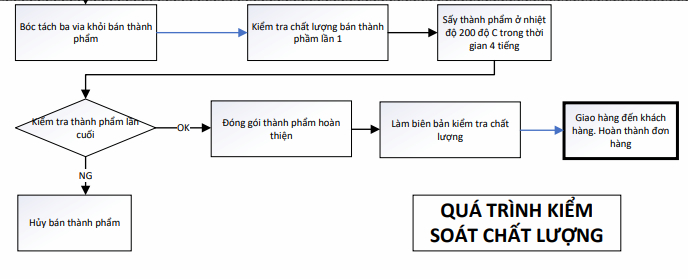

- Quality inspection: Each product is carefully inspected before packaging and delivery.

6. Delivery of Goods

- Packaging: Finished products are securely packaged to avoid damage during transport.

- Shipping: Goods are delivered to the customer’s address as agreed.

RAW MATERIAL CONTROL PROCESS

PRODUCTION PROCESS

QUALITY CONTROL PROCESS

Notes

Production time:

Depends on product complexity, quantity, and customer requirements.

Cost:

Costs vary according to material type, quantity, product complexity, and surface-quality requirements.

Silicone materials:

There are many silicone material types with different properties. Choosing the right material is critical to ensure the final product meets customer expectations.

Tel : 0936.08.03.82

MINH FAST COMPANY LIMITED

Office address: No 1/19 Luong Khanh Thien Street, Tuong Mai Ward, Hoang Mai District, Hanoi, Vietnam.

Factory : Km 33 – ĐT 379 – Văn Giang – Hưng Yên

Tel: 0936.08.03.82

Email: Minhfastsales@gmail.com

Fanpage: https://www.facebook.com/minhfastsilicone

Website: https://giacongsilicone.com