- What is a round rubber gasket?

- Application of heat-resistant round rubber gasket

- The process of processing silicone rubber gaskets according to samples

- Step 1: Prepare the gasket sample

- Step 2: Prepare ingredients

- Step 3: Handle the silicone gasket

- Step 4: Quality inspection

- Order heat-resistant round rubber gasket processing

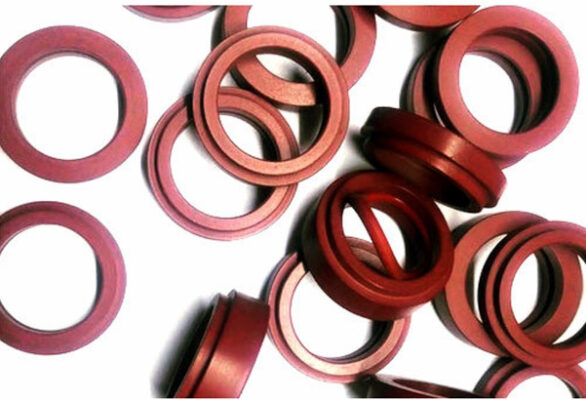

Small round rubber gaskets with high flexibility are widely used in many industries. Find out the detailed specifications of quality round rubber processing through the article below.

What is a round rubber gasket?

Round rubber gasket is a type of gasket made of flexible rubber material and has a round shape. This accessory is used to seal joints in many different industries. Oring round rubber gaskets come in many sizes depending on the purpose of use. The round gasket products in each detail of each machine are different.

Characteristics of round rubber ron processing

| Materials | Heat-resistant rubber |

| Hardness | 55 shore A – 80 shore A |

| Colour | Clear white, red, black, blue |

| Material properties | Elastic, soft, odorless |

| To bear temperature | Working temperature below 220 degrees Celsius, with a maximum of 250 degrees Celsius |

| Density | 1,3g/cm3 |

| Food | Food safety and hygiene,. Certified by Rosh, FDA, can be used in medicine |

| Chemicals | Resistant to chemical plating, paint, some dilute acids. However, it is not resistant to acidol, methanol |

See more: Ron products with quality round rubber gaskets

Application of heat-resistant round rubber gasket

Heat-resistant round rubber gaskets have many sizes 6×6, 8×8, 10×10, 12×12, 14×14, 16×16, 18×18, 20×20 ... Used to place at the door grooves of the drying cabinet, boiler grooves... for the purpose of sealing, avoiding temperature loss to the external environment, ensuring the temperature of the drying oven, drying cabinet is stable. The size of round rubber gaskets can be customized according to customer requirements. Some other requirements such as: adding holes inside, adding ledges, adding edges on the gasket surface...

The process of processing silicone rubber gaskets according to samples

The process of processing silicone rubber gaskets according to the sample is carried out according to the following steps:

Step 1: Prepare the gasket sample

Sample preparation is the first important step before starting to manufacture rubber gaskets. The model can be a pre-produced part or a 3D model created by design software. This model will be used to mold round gaskets and ensure the gasket has the correct size and shape.

Step 2: Prepare ingredients

After taking samples, the next step is to prepare raw materials for processing. The main material is silicone rubber, which is heat-resistant, chemical-resistant and highly flexible. The composition of raw materials varies depending on the technical requirements of the product to be processed.

Step 3: Handle the silicone gasket

Use molds:

It is an important tool in the process of machining silicone rubber gaskets according to the sample. Forms can be created using CNC machining or using traditional machining techniques such as turning, milling, grinding... The mold processing process needs to ensure high accuracy to give birth to gaskets with good sealing characteristics.

Gasket processing:

Put the material prepared in step 2 into the mold to ensure that the pressure in the mold does not change during the machining process. Click and drop the device to remove air bubbles and increase product adhesion.

Step 4: Quality inspection

Silicone gaskets are checked after machining to ensure that they meet the standard. Quality inspection can be done with measuring tools and inspection techniques such as size, hardness, strength, tightness, etc.

Order heat-resistant round rubber gasket processing

Before ordering processing, you should choose a reputable and experienced supplier to ensure product quality. If you are looking for a quality silicone rubber processing address, Minh Fast is the first choice for you. Minh Fast Company specializes in manufacturing and processing high-quality gaskets. With many years of experience and extensive knowledge of silicone rubber, we are proud to be a reliable partner of many customers in Vietnam and Internationally. To order round ron processing, you need to provide some technical information about Size, material, hardness of silicone, quantity, other requirements…

See more: High quality temperature-resistant silicone rubber gaskets at Minh Fast

Minh Fast meets any other special requests of customers. Contact us for more advice on price, delivery time and ordering process.

![]()

Certification

Packaging & Shipping

MINH FAST COMPANY LIMITED

Head office: No. 1/19 Luong Khanh Thien Street, Tuong Mai Ward, Hanoi city, Vietnam.

Phone/zalo/whatsapp: 0084.8899.14599

Email1: Thamsiliconetkv@gmail.com

Email2: Minhfastsales@gmail.com