- What is a chocolate mold?

- How to use a Valentine chocolate mold

- Step 1: Prepare ingredients and tools

- Step 2: Melt the chocolate

- Step 3: Pour into the Valentine chocolate mold

- Step 4: Chill to set

- Step 5: Remove the mold and decorate

- Step 6: Store and gift

- Why use a silicone chocolate tray? Comparison with other types

- Technical specifications for silicone chocolate molds

- Criteria for choosing a silicone chocolate mold manufacturer

- Food-safe material

- Production capability and experience

- Custom design and OEM/ODM capability

- Strict quality control

- Reasonable pricing and good support

- Delivery and after-sales service

- Minh Fast – Quality silicone chocolate mold manufacturer

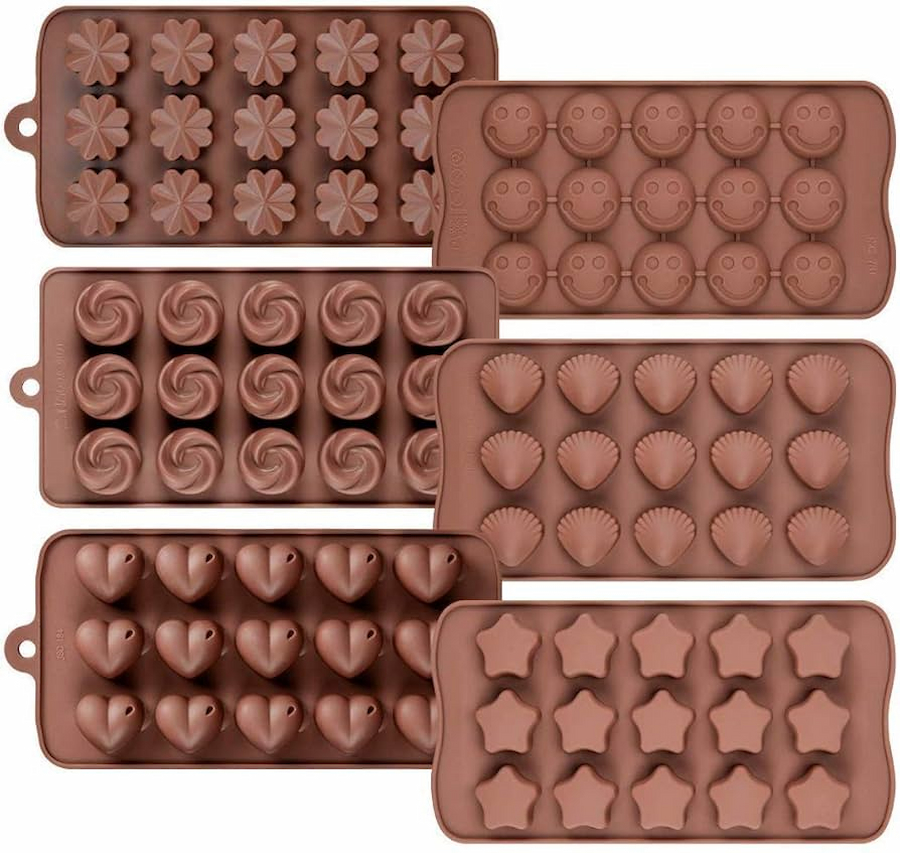

Chocolate molds are not only used in industrial production but are also popular for baking, handmade gifts, or home preparation. With good heat resistance, easy cleaning, and reusable many times, chocolate molds are a great helper for users to create chocolate pieces in shapes like circles, stars, etc., beautifully, professionally, and with a personal touch.

What is a chocolate mold?

A chocolate mold is a tool used to shape chocolate after melting, helping to create chocolate pieces with various shapes, sizes, and patterns such as hearts, stars, letters, or cute animal shapes. Depending on the use, chocolate molds can be made from silicone, plastic, stainless steel, or polycarbonate – among which silicone molds are the most popular due to their flexibility, non-stick properties, and ease of removing chocolate after solidifying.

How to use a Valentine chocolate mold

Step 1: Prepare ingredients and tools

-

Dark chocolate, milk chocolate, or white chocolate (according to taste).

-

Valentine chocolate mold (preferably silicone or polycarbonate for easy chocolate removal).

-

Heat-resistant pot or bowl, spoon, and wrapping paper.

Step 2: Melt the chocolate

-

Cut the chocolate into small pieces and melt it using a double boiler.

-

Stir until smooth and shiny. You can add a little butter or condensed milk if you want softer chocolate.

Step 3: Pour into the Valentine chocolate mold

-

Use a spoon or piping bag to pour melted chocolate into the mold.

-

Tap the mold lightly on the table to remove air bubbles, ensuring smooth and even chocolate.

Step 4: Chill to set

-

Place the mold in the refrigerator for 15–30 minutes until the chocolate hardens completely.

-

Do not leave too long in the freezer to avoid whitening or breaking the chocolate when removed.

Step 5: Remove the mold and decorate

-

Gently take the chocolate out of the mold.

-

Optionally decorate with colored chocolate, nuts, or powdered sugar to enhance appearance.

Step 6: Store and gift

-

Keep chocolate in a sealed box, in a dry and cool place.

-

Wrap with foil or colored paper for a more romantic Valentine’s gift.

With a Valentine chocolate mold, you can easily create chocolate pieces in heart shapes, “Love” letters, or special symbols – a sweet, delicate, and emotional gift for your loved ones.

Why use a silicone chocolate tray? Comparison with other types

1. Why choose a silicone chocolate tray?

-

Flexible and naturally non-stick: Makes it easy to remove chocolate without breaking or deforming.

-

High and low heat resistance: Temperature range from -40°C to 230°C, suitable for both chilling and pouring melted chocolate.

-

Absolutely safe: Made from food-grade silicone, free from BPA and harmful substances, safe for health.

-

High durability and reusable: Does not become brittle, crack, or fade like plastic; does not oxidize like metal.

-

Easy to clean: Simply rinse with warm water or use a dishwasher.

2. Comparison with other mold types

| Criteria | Silicone Chocolate Tray | Plastic Mold | Stainless Steel / Metal Mold | Polycarbonate Mold |

|---|---|---|---|---|

| Material | Food-grade silicone, safe, BPA-free | Common plastic, may contain harmful substances | Stainless steel or aluminum | Premium hard plastic, shiny |

| Flexibility & Non-stick | Very good, easy to remove chocolate without breaking | Sticks easily, may crack | Needs buttering | Non-stick, shiny surface |

| Heat Resistance | -40°C to 230°C, flexible | 0°C to 70°C, low | High, conducts heat quickly | Medium, can deform when hot |

| Durability & Reusability | High, not brittle, no fading | Breaks easily, ages quickly | Durable but heavy | Durable, expensive |

| Food Safety | Very safe, FDA/LFGB certified | May not be certified | Safe | Safe |

| Cleaning | Easy, non-stick | Scratches easily, hard to clean | Needs careful scrubbing | Easy to wipe, careful needed |

| Cost | Reasonable, economical | Cheap | High | High |

| Suitable for | Handmade chocolate, small production | Beginners, trials | Large-scale production, durability | Premium brands, aesthetics |

| Overall | Optimal – flexible, safe, easy to use | Easily damaged, less durable | Durable but hard to handle | Beautiful but costly |

See more: Bear-shaped cookie mold – silicone bear mold

Technical specifications for silicone chocolate molds

When producing or customizing chocolate molds, technical specifications are important to ensure accuracy, durability, and food safety. Commonly applied standards:

| Category | Specification | Note |

|---|---|---|

| Material | 100% food-grade silicone or medical-grade silicone | FDA, LFGB certified, BPA, PVC, lead-free, safe |

| Hardness | 40–60 Shore A | Ensures flexible yet firm to remove chocolate without deformation |

| Heat Resistance | -40°C to 230°C | Suitable for chilling and pouring melted chocolate, microwave, freezer, dishwasher |

| Mold Thickness | 1.5–3 mm | Depends on chocolate size and design |

| Standard Mold Size | 10 × 20 cm, 15 × 30 cm, or customizable | OEM/ODM available |

| Color | Customizable with food-safe color powders | Usually brown, red, pink, gray, or transparent |

| Production Technology | Compression molding or injection molding | Ensures smooth surface, no air bubbles, no silicone odor |

| Surface Finish | Glossy or slightly matte | Affects chocolate’s final shine |

| Packaging | PE bag, paper box, or branded packaging | Logo, product code, and instructions can be printed |

| Quality Standards | ISO 9001, BSCI, SGS, FDA, LFGB | Meets international export and food safety standards |

A standard silicone chocolate mold ensures uniform chocolate pieces, easy removal, no air bubbles, and sharp shapes while being safe, durable, and reusable.

Criteria for choosing a silicone chocolate mold manufacturer

Food-safe material

Prefer manufacturers using 100% food-grade or medical-grade silicone with FDA/LFGB certification, BPA-free.

Production capability and experience

Choose units with experience in silicone molding, precision control, and modern compression or injection molding equipment.

Custom design and OEM/ODM capability

Professional manufacturers can create molds with custom designs, brand logos, or special sizes.

Strict quality control

Prefer factories with ISO 9001, BSCI, SGS certification and batch inspection processes to ensure smooth molds, no air bubbles, and easy chocolate removal.

Reasonable pricing and good support

Transparent pricing, bulk order discounts, and technical support.

Delivery and after-sales service

Reliable manufacturers ensure on-time delivery, careful packaging, and return policies for defective or wrong samples.

Minh Fast – Quality silicone chocolate mold manufacturer

Minh Fast specializes in producing and customizing chocolate molds according to requirements, meeting international FDA and LFGB food safety standards. With modern molding lines and experienced technical staff, Minh Fast delivers durable, smooth-surfaced, easy-to-release molds with heat resistance from -40°C to 230°C.

We provide design and OEM/ODM mold customization, support brand logo printing, and offer various shapes such as round, heart, flower, chocolate bars, suitable for businesses, bakeries, and handmade gift shops.

Minh Fast is committed to providing high-quality, safe silicone molds at competitive prices with advisory and delivery services, ensuring peace of mind for every order.

See more: Silicone heart mold – standard customized heart mold

![]()

Certification

Packaging & Shipping

MINH FAST COMPANY LIMITED

Head office: No. 1/19 Luong Khanh Thien Street, Tuong Mai Ward, Hanoi city, Vietnam.

Phone/zalo/whatsapp: 0084.8899.14599

Email1: Thamsiliconetkv@gmail.com

Email2: Minhfastsales@gmail.com